FeedBack

Feedback – Posture Correction for Retail & Warehouse Employees

Every day, employees in retail and warehouses perform a significant number of lifts. In a stressful environment with fast pace only a few of these lifts are done correctly. As a result, the employees’ backs take the hit, and they end up getting injured. Feedback corrects the posture for safer lifts – without slowing down the pace.

"Every shift is like a workout"

– “Erik”, warehouse employee

Physical Strain and Ergonomic Issues

Repetitive Lifting Injuries

Many employees reported chronic back pain, primarily due to improper lifting techniques when handling heavy boxes. Although they had received training on ergonomic lifting, the pressure to meet tight deadlines often led to improper methods, compromising their safety.

Manual Handling of goods

Tasks like bending, reaching, and twisting, especially when dealing with high shelves or awkwardly placed items, contributed to musculoskeletal discomfort. We observed a consistent neglect of proper posture when employees were under time constraints.

Faulty Designed Tools

Employees frequently suffered from hand and arm injuries, largely due to the use of poorly designed knives and cutting tools. In many cases, workers lacked access to ergonomically optimized tools, increasing the likelihood of cuts and repetitive strain injuries during the unpacking process.

“One has to be ready by a certain time, so it’s stressful.”

– “Maria”, warehouse employee

"It’s easy to forget to lift correctly when everything has to be done so quickly. I don't have time to think."

– “Berit”, grocery store employee

Mental and Emotional Strain

High-Stress Environment

Tight schedules and fluctuating workloads put considerable mental strain on employees, with many reporting feelings of burnout. The combination of physical labor and the constant need to keep pace with incoming deliveries created a high-pressure environment.

Reduced Focus on Safety: Under stress, employees often sacrificed proper safety protocols in favor of completing tasks quickly, which further contributed to the likelihood of injuries and decreased job satisfaction.

Reduced Focus on Safety

Under stress, employees often sacrificed proper safety protocols in favor of completing tasks quickly, which further contributed to the likelihood of injuries and decreased job satisfaction.

Inefficient Workspaces and Cluttered Areas

Cramped Storage Conditions

In many warehouses, the limited available space prevented the effective use of equipment such as forklifts, forcing workers to rely on manual handling. The cluttered layout also led to unsafe working conditions, as employees had to navigate narrow aisles while carrying heavy loads, increasing the risk of accidents.

Inconsistant Workflow

We observed inefficiencies in the workflow, with certain tasks requiring employees to repeatedly bend, stretch, and twist to reach goods. This lack of standardized processes contributed to unnecessary physical strain, highlighting the need for better workplace organization and tool placement.

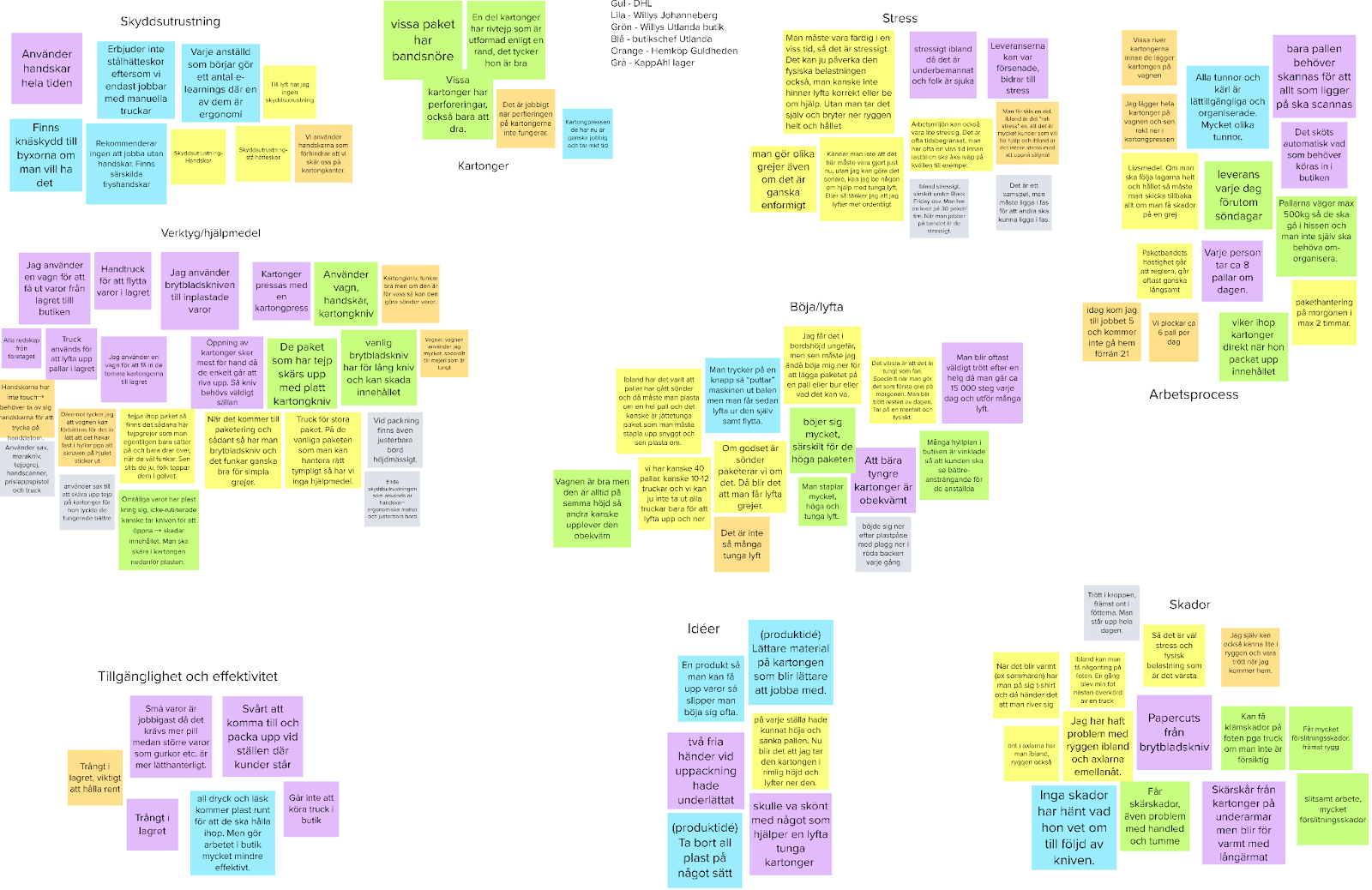

Affinity Diagram

A KJ analysis was conducted to process qualitative data from interviews and observations. Each interview and observation was color-coded on Post-its in Mural. Relevant quotes and findings, including dissatisfaction and discomfort, were noted and organized.

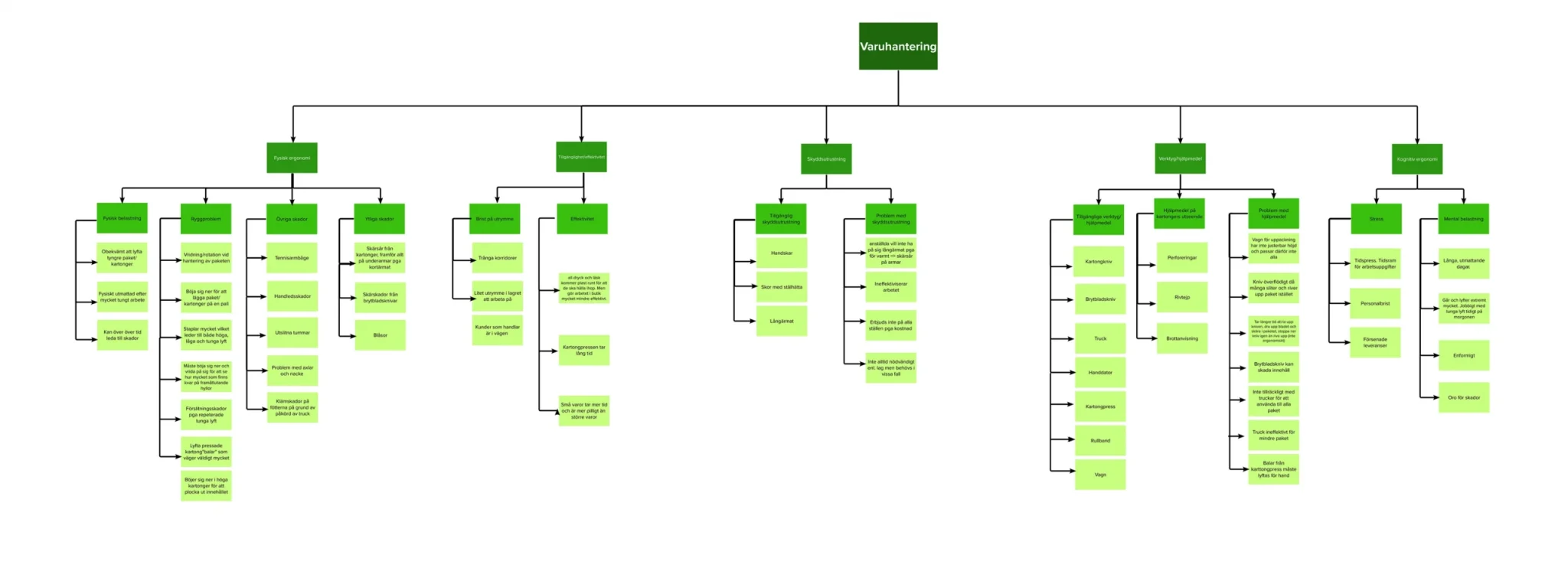

Tree Diagram Breakdown

All issues were broken down in

Concept – Feedback

Feedback reminds the employee to lift correctly throughout the work shift. When the back is bent, the straps tighten and force a better posture. Shoulders are pulled back, back becomes straight, and forces the user to bend the legs to lift. An ergonomic lift is created and the back is spared.